By: Shawn Brannan, Dustin Hesse

Nestled in Princeton, Minnesota, Crystal Cabinet Works is one of America’s largest custom cabinet makers. Its 200,000 square-foot facility anchors the industrial park the manufacturer calls home. Founded in 1947, Crystal Cabinet Works produces high-quality, award-winning designs. Their excellent work led to them needing more space.

Before 2007, Crystal Cabinet Works had been forced to move its production machines (CNC routers, edge banders, joiners, planers, etc.) to keep roof leaks from landing on the machines, raw goods, or finished products. In 2007, All Elements, Inc. installed Crystal Cabinet Works’ first Duro-Last 40-Mil PVC roof to stop the leaks.

The All Elements Commercial Roof Solution

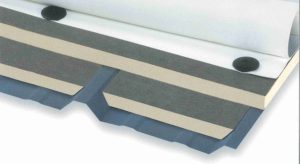

Both the existing and expanded Crystal Cabinet Works buildings were constructed of steel with metal roofs. All Elements took these roofs from steel with ribs to smooth, Energy Star-rated, white PVC membranes. This required several steps.

First, we filled in the area between the steel roof panel’s ribs with insulation. Then, we installed an insulation coverboard to smooth over the transitions from metal panel to insulation. Finally, our team mechanically fastened large, custom-made sheets of Duro-Last membrane and hot-air welded them together to make a seamless roof. As Crystal Cabinet Works expanded its facility, we’ve repeated this process. Now, nearly all of the facility is covered with Duro-Last 40-Mil PVC membrane.

Expanding Its PVC Roof

Last winter, Crystal Cabinet Works added another 22,000 square feet to its facility. They wanted to have the same confidence under their new roof that they have with the rest of the building.

When planning for their new building, Jared Nierengarten and the Crystal Cabinet Works crew made it clear to their general contractor that they wanted a Duro-Last roof installed by All Elements. Why was that?

First, Jared appreciated the quality of the product and workmanship. The standard Duro-Last warranty covers labor and materials with no dollar limit for 15 years. It also covers consequential damages for 15 years. A warrantied leak that damages or causes a loss to machines, raw goods, or final product could be covered under warranty from the manufacturer. The warranty is a nice feature, but it is a result of the high-quality product and its equally high standards for installation.

Second, with a Duro-Last roof, Crystal Cabinet Works “never thinks about the roof leaking,” Jared reports. “We had to move machines to where the roof wasn’t leaking before All Elements installed the Duro-Last roof. We never think about a leak now.”

Finally, Jared and his team appreciate the excellent service All Elements provides. When a change is needed that involves the roof, like additional penetrations or moving equipment, All Elements is there, working in coordination with the owner and other contractors and making it easy for the owners.

With the new construction project, we did not have to infill any ribbed metal panels to infill. All Elements installed new ISO insulation over typical steel roof decking. Tying the new roof into the existing one is nearly effortless. We clean the old roof membrane with a wet rag and hot-air weld the new membrane to it. Yep, it’s that easy! Check out the photos, then contact the All Elements team for a consultation on your commercial roof project.